S-Series Custom Enclosure

The S-Series Enclosures are pre-assembled intended for use with the ISIMET Utility Controller. Each solenoid “station” is assembled with a threaded main ball valve cut-off and union fittings. All piping joints are tested for tightness. However, the union at each station is loose fit for ease in field installation. The stations are secured to aluminum strut supports by means of pipe clamps.

NOTE:

To insure safety and to prevent premature coil failure, it is recommended that solenoid valves be left de-energized when utility service is not in use.

Series 4000

At each science classroom provide a Utility Controller with door panel mounted switches to activate remote solenoids and relays to control the domestic water, natural gas, and electrical convenience outlets at student work stations. The Controller shall be equipped with a key activated safety switch and door panel mounted momentary panic button assembly. Controller shall be integrated with the energy management system and monitored by the building alarm system.

Optional Circuits:

Provide remote auxiliary circuit to permit connection of LA Series Companion Controller to operate circuits and solenoids at the teacher prep area or demonstration station.

Provide restrictive control to exhaust fans and fume hood.

Other Uses for the Utility Controller

Home Economics Classrooms

The same control capabilities used for the safe activation of science classroom student workstations can also control activation of potentially dangerous appliances such as gas and electric stoves, blenders, and food processors. The risk of accidental shock or burn is greatly reduced because the instructor can determine which appliances a student may activate.

Master Controllers

Utilizing in a design any of our standard Controller Units or Time Sequencing Units with a series of Remote Operators can create a Master-to-Slave operating environment. This type of control package is specifically intended for use in research lab facilities where a vast number of laboratories require only the emergency control of the fuel gas systems. Consult the factory for specific features than can be offered to accommodate the design requirements for specific projects.

UtC Series 5000/6000

The 5000 / 6000 Series Shop Controllers can be utilized to control multiple utility services, gas and electrical convenience outlets that are commonly used in either educational, research or medical facilities.

Standard fitted from 4 – 9 output circuits depending upon the project requirements. Units can be custom expanded to up to twenty (20) outputs. This series of the Utility Controller is also ideally suited for use in the shop classrooms to activate such devices as table saws, grinders, and other power tools in the classroom.LS Series

The LS Series of our Utility Controller performs the same functions as our standard models with many added features. Each unit is equipped with a radio frequency receiver/decoder that enables a Hand-Held transmitting Keyfob to communicate commands from the instructor remotely from anywhere within the classroom.

Choosing from a group of five hundred unique secure codes the Controller and Receiver are encoded alike, permitting each unit within a facility to operate independently without the fear of interference from other units.

The receiver’s antenna is mounted externally to the Utility Controller at the base for flush mounts and on top for surface mounts. The antenna for flush mount units is concealed within the wall cavity. Transmission range is not impaired by this feature.

The Hand-Held Keyfob has a 100 + ft. range and is furnished with our custom ISIMET Lanyard that enables the instructor to wear the Controller conveniently around his or her neck during times when the Utility Controller is in use. During non-use periods, it is recommended that the Hand-Held Keyfob be placed securely out of reach of other occupants of the classroom.

The standard Keyfob is equipped with five buttons. The center button activates panic. Each of the out-facing buttons will disable one each of the three services controlled by the unit. Pressing the lower Key button will reactivate those services disabled by the previous action. Services in the OFF position at the Controller are not affected by activating buttons on the Keyfob

RA Controller

This RA Series of the Utility Controller features many of the same configurations and options as the Standard Controller but is designed to provide ease in a retrofit situation. Intended as an upgrade to present control of the science classroom utilities without the refurbishing of the entire room. Output circuits should comply with ISIMET output circuit requirements.

Specific Features:

-

Allows the Door Panel component to be “Surface Mounted”.

Permits the Controller to be located remotely from the classroom.

Eliminates wall repairs and resurfacing.

Key Switch resets Panic.

Can be Multi-Packaged for up to 4 individual systems.

Available in White Powder Coat Wall Panel Only.

Single systems can be upgraded to the LS Series.

Additional Features and Offerings:

-

Limited design assistance provided to the school.

System can be installed by on-site maintenance staff.

Auxiliary and Remote Circuits are available.

LA Series

The LA Series Controller operates as a single or dual output controller where the application does not require the positive remote enabling authority or monitoring capabilities typically anticipated when specifying our Standard Utility Controller.

This unit is ideally suited for the classroom where the instructor’s desk is the only workstation having utilities present or where restricted operation of a single utility such as natural gas is required. Resets will be required when stand alone solenoids or solenoids provided by other manufacturers are used. Additionally, the LA Series integrates easily into the Utility Controller system, thus permitting a single source workstation to be controlled by one of the remote output circuits at the controller.

Features:

Panic Button,Key Switch, Control Switch, Panel Mounted LEDMounting Variations:

-

Casework, Flush Wall Mount, Surface Mount

Remote Input:

-

The LA Series will accept two 24-vac input signals from a remote/integrated operating system permitting that system to deactivate the unit based on time sequencing and/or alarm notification.

Monitoring Output:

LA Series provides a 24-vac output signal and a dry-contact to a remote/integrated operating system permitting that system to monitor the unit for “panic”. LS-Line Of Sight: The RF Module can be integrated into the operating function of the 4.41 version pcb.Fire House Controller

Application: The FLA Series Controller operates as a dual output controller to operate fuel gas outlets as well as electrical devices located within the kitchen in a Fire Station. Input terminals equipped with a delay function will turn OFF all connected appliances when a notification signal is received for a fire or other emergency response.

The Alarm Signal initiated by the Fire Response System for the Fire Station will automatically shut down the kitchen’s utilities and devices that are operated by the Controller when this System is integrated with the FLA Unit.

A Time Delay circuit on the Version 4.6 FLA Controller allows for up to ten (10) minutes to elapse before shutdown occurs. This delay may prevent a kitchen shutdown in the event that the Alarm is withdrawn during this delay period.Further, if the response is not such that normal activities at the station must be altered for some of the staff, an OverRide switch on the unit will stop the shutdown.

A 10 amp, 120 vac circuit is available to operate the wall plug at the gas oven

Laboratory Service Panel

The ISIMET Laboratory Service Panel operates as a single output controller incorporating either a solenoid valve assembly or electrical contacts along with the digital switching mechanism within a single enclosure. An internal junction box houses the 120-vac line voltage along with transformer and circuit board. The Laboratory Service Panel is not suitable for applications directly exposed to weather or wet conditions.

Variations:

Solenoid - The unit is equipped for either natural gas or fluid system applications (domestic water). This unit features a manual shut-off valve with a 24-vac N/C solenoid with fittings. The solenoid is pre-wired to the output circuit at the printed circuit board. Refer to ISIMET Solenoid Specification for valve specifics. Sizes from ½” – 1” IPS. Valve Station Suffix “TUT” – Double Threaded Union through 1”. “TU” – Threaded Union greater than 1”. “XU” – non-union on all fuel gas systems but piping is provided with added union. All units are provided with rubber grommets – Standard. Fluid systems are optionally provided with a 20 mesh Y-Strainer. Electrical - Either a three (3) pole definite purpose contactor from 30 – 50 amp, or a four (4) or eight (8) pole mechanically held lighting contactor is provided within the enclosure.Master Controller:

Combining the time sequencing and master operator features of the ISIMET Integration Interrupt Time Control Device – ITC, the Service Panel can perform the Master in a Master-to-Slave Operating Environment. Incorporating ISIMET Remote Operators with individual 120-vac solenoids at each laboratory with the Service Panel in a central location offers an ideal solution to facility management of large research facilities where the control criteria for utilities is less demanding than that of the typical public school laboratory.

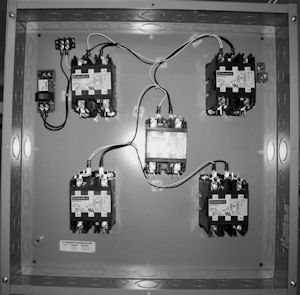

Custom Assemblies:

Units can be custom fabricated to meet specific project requirements. Multi-solenoid assemblies using the ISIMET 24X24 Enclosures are available for a wide range of applications. Contact a factory representative.

LA Series 4000

The Time Delay “OFF” Controller operates as a single output controller where the application requires restrictive activation of a utility with a delay “OFF” after first activation.

This unit is ideally suited for shower units in correctional facilities or drug testing facilities where operation or use of the showers or lavatory facilities will be limited to specific time periods, and where operation “ON” is established by authority. Style 44’s use includes wash-down systems where predetermined cycled operation is required but with capabilities for short cycle activation on demand.

The delay “OFF” relays are housed in a remotely located enclosure with a screw-on cover. The active “ON” switching incorporates a momentary key-switch for Operation and a push-button “STOP” switch for immediate deactivation and are mounted on a stainless steel wall plate.

Features:

Operation - Key Switch: Momentary switch for an “ON” Cycle.

Push Button Switch: Contacts disengage the system requiring re-keying to active “ON”.

Wall Panel: Brushed Stainless Panel W/ vandal resistive hardware.

(labeling “OPERATE” – “ON” - “STOP”)

Switch Wall Box: Powder coat W/ hardware for flush mounting.

Controller Wall Box: Powder Coat W/ solid cover and mounting hardware.

(Operating switches can optionally be mounted on the enclosure panel whereby the wall panel & box are omitted.)

DLA Series Controller 1 & 2

The DLA Series Controller is used to operate remotely located 12-vdc latching solenoids for domestic water services in Healthcare Facilities or in a Drug Testing Laboratory.

This unit is provided with ISIMET latching circuit boards that permit a signal to latch the solenoids ON and OFF, controlling the water supply to the restroom facility. In the case of patient rooms in a Healthcare Facility the ON circuit on the primary pcb enables the water to be turned ON and OFF either remotely or locally.

For Drug Testing Labs, the unit is intended to control the water flow to the restroom where drug samples are deposited. One board is designated to operate ON-OFF the water supply valves. A secondary board permits solenoids to operate ON when the primary solenoids are OFF, thus allowing for drain-down of the piping. (MAX two solenoids per circuit board)

DLA Series Controller 3

The DLA Series Controller is used to operate remotely located 12-vdc latching solenoids for domestic water services in Healthcare Facilities or in a Drug Testing Laboratory.

This unit is provided with ISIMET latching circuit boards that permit a signal to latch the solenoids ON and OFF, controlling the water supply to the restroom facility. In the case of patient rooms in a Healthcare Facility the ON circuit on the primary pcb enables the water to be turned ON and OFF either remotely or locally.

For Drug Testing Labs, the unit is intended to control the water flow to the restroom where drug samples are deposited. One board is designated to operate ON-OFF the water supply valves. A secondary board permits solenoids to operate ON when the primary solenoids are OFF, thus allowing for drain-down of the piping. (MAX two solenoids per circuit board)

- S-Series Enclosures

- S-Series Enclosures

- E-Series Enclosures

- E-Series Enclosures

- E-Series Custom Enclosures

- E-Series Custom Enclosures

- UtC Series 4000

- ISIMET UtC Series

- UtC Supplementals

- UtC 5000/6000 Series

- ISIMET UtC Series

- UtC Supplementals

- PDFInstallation, Maintenance, Operations, and Start-up Instructions

- Controllers RA/RLA Series

- RA/RLA Series

- PDFFire Rating

- PDFFire Rating Installation Instructions

- LA Series

- LA 4.41 Series

- LA 4.42 Series

- PDFFire Rating

- PDFFire Rating Installation Instructions

- LSP Series

- LSP Series

- PDFFire Rating

- PDFFire Rating Installation Instructions

- LA-4000 Series

- LA-4000 Series

- Controllers DLA Series

- DLA Series O&M

- DLA Checklist

- Controllers DLA Series

- DLA Series O&M

- DLA Checklist

- Controllers DLA Checklist

- Controllers DLA Checklist/Startup

Address: 103 C J Wise Naples, TX 75568

877-897-2371

Isimet Phone: (903) 897-0737

Isimet Email: Sales@isimet-mapa.com

Mapa Products Phone: (903) 897-2371

Email: customerservice@isimet-mapa.com

Copyright © 2016 · All Rights Reserved · Isimet Mapa LLC